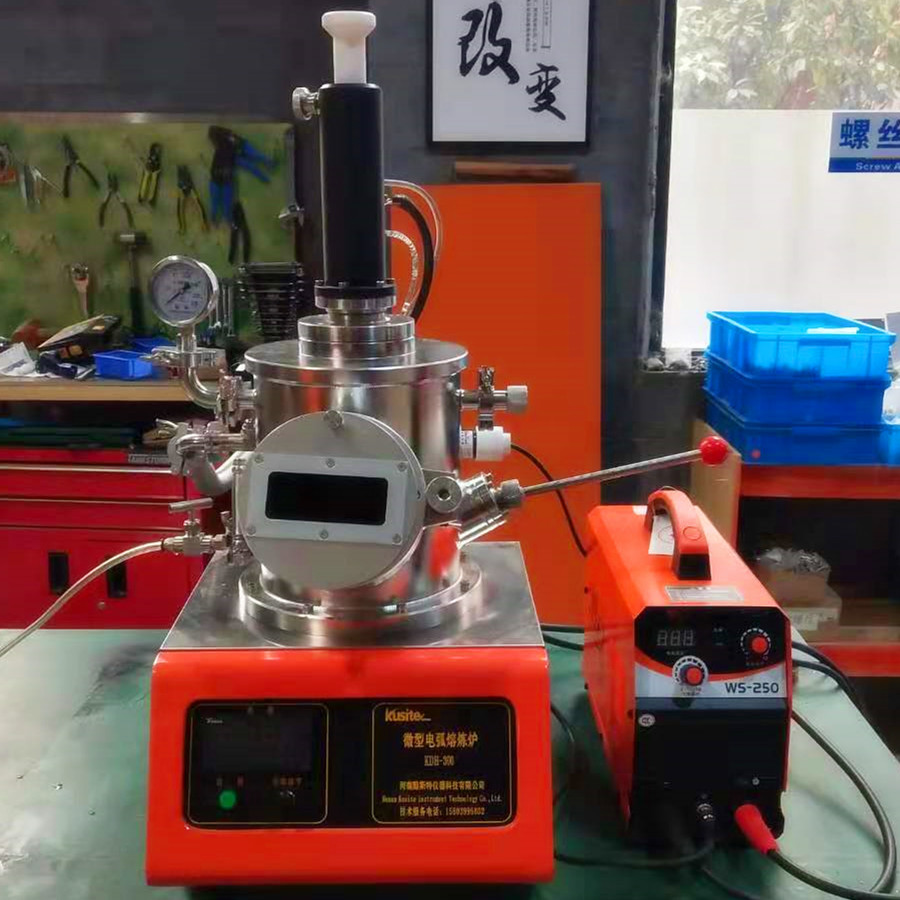

- 酷斯特微型真空电弧炉非标定做电弧炉KDH-300

详细信息

品牌:酷斯特 型号:KDH-300 加工定制:是 产品别名:真空电弧炉纽扣炉 产品用途:用于熔炼高熔点金属/合金 一、微型真空电弧炉非标定做电弧炉产品简介

一、微型真空电弧炉非标定做电弧炉是我公司根据科研单位实验要求精心研发的产品主要用于熔炼高熔点金属/合金,广泛应用于高熔点难熔金属、金属合金等,适用于高校及科研院所进行真空冶炼新材料的科研与小批量制备。本设备采用桌面式全不锈钢设计,立体感强,操作方便,占地空间小。

二、微型真空电弧炉非标定做电弧炉产品特点

1、熔炼温度高,熔炼温度可达3500℃

2、全不锈钢设计真空腔体小,密封性好,可快速抽真空,快速充氩气,效率快及氩气消耗非常少

3、水冷铜电极可360度移动,操作灵活,同时水冷坩埚小巧可更换,可定制。

4、带翻料装置,克服物料单面熔化不匀的局面

5、可配置高真空系统,炉体配置有快接接口,方便拆卸

6、采用超温保护和加装滤光玻璃保护眼睛

7、桌面式设计,精巧轻便,移动灵活

8、设备小巧,功耗小,但可以熔炼较多容量的产品,解决科研经费不足,大容量设备能耗,资金消耗大 的弊端。三、微型真空电弧炉非标定做电弧炉结构简介

(纽扣炉)微型电弧炉小型电弧炉由真空室、水冷电极、水冷铜模、气路系统、坩埚升降系统、机壳和

熔炼电源组成。

1、真空室:采用304全不锈钢结构,质感强烈,密封性好,即可高高温高真空下使用,也可在保护气氛下使用

2、水冷电极:顶部和底部放分别通有正负电极,顶部为机械手结构,可方便的在几个样品之间移动,密封采用动密封装置,保证在移动过程中的真空度。

3、水冷铜模:提供三工位水冷铜坩埚模具,可以一次熔炼较多容量的产品,另可根据客户要求定制;

4、气路系统:由压力表、真空阀、压力罐、手动阀门和管路组成,可方便的实现手动充放气,还可实现超压排气,保护真空室安全。

5、水冷坩埚系统:底部水冷铜模固定在炉低密封牢固,冷却性好,也好拆卸,和更换带吸铸带搅拌的多功能坩埚。

6、机壳:结合国内外设备外观经验,根据自身设备特点,设计出合理机壳,外表喷塑处理;

7、熔炼电源:定制的专用电弧熔炼电源,操作简单,结构小巧

I. Brief Introduction of KDH-300B Small Non-consumable Vacuum Arc Furnace Non-consumable Arc Furnace Products

1. KDH-300B small non-consumable vacuum arc furnace is a kind of non-consumable arc furnace developed by our company according to the experimental requirements of scientific research institutes. It is mainly used for smelting high melting point metals/alloys, widely used for high melting point refractory metals, metal alloys, etc. It is suitable for the research and small batch preparation of new materials for vacuum smelting in universities and scientific research institutes. Desktop stainless steel design is adopted for this equipment, which has strong stereoscopic sense, convenient operation and small space occupation.

2. Product Characteristics of KDH-300B Small Non-consumable Vacuum Arc Furnace

1. High melting temperature, melting temperature up to 3500 C

2. All stainless steel design vacuum chamber is small, sealed well, can quickly vacuum, rapid argon filling, fast efficiency and very little argon consumption.

3. The water-cooled copper electrode can be moved 360 degrees and operated flexibly. At the same time, the water-cooled crucible is small and can be replaced and customized.

4. The situation of uneven melting of customer service materials with material turning device

5. Configurable high vacuum system. Furnace body is equipped with quick connection interface, which is convenient for disassembly.

6. Protecting eyes by overtemperature protection and adding filter glass

7. Desktop design, delicate, portable and flexible

3. Brief introduction of the structure of KDH-300B small vacuum arc furnace with non-consumable arc furnace

(button furnace) miniature electric arc furnace consists of vacuum chamber, water-cooled electrode, water-cooled copper mould, gas path system, crucible lifting system, shell and

Composition of smelting power supply.

1. Vacuum chamber: 304 stainless steel structure, strong texture, good sealing, can be used in high temperature and high vacuum, also can be used in protective atmosphere.

2. Water-cooled electrodes: There are positive and negative electrodes at the top and bottom respectively. The top is a manipulator structure. It can move between several samples conveniently. The seal adopts dynamic sealing device to ensure the vacuum degree in the process of moving.

3. Water-cooled copper mould: There are 5 8*25 sample pots in the standard copper mould, which can be customized according to customers'requirements.

4. Gas system: It is composed of pressure gauge, vacuum valve, pressure tank, manual valve and pipeline. It can realize manual charging and discharging conveniently, and can also realize over-pressure exhaust to protect the safety of vacuum chamber.

5. Water-cooled crucible system: the bottom water-cooled copper mould is fixed in the furnace with low sealing and firm, good cooling, good disassembly, and replacement of multi-functional crucible with suction casting belt stirring.

6. Shell: Combining with the external experience of domestic and foreign equipment and according to the characteristics of their own equipment, reasonable shell is designed and sprayed.

7. Smelting power supply: customized arc smelting power supply, simple operation, compact structure

-

供应商的其他相关信息

查看更多

-

河南酷斯特仪器科技有限公司联系热线

河南酷斯特仪器科技有限公司联系热线

15803995802酷斯特微型真空电弧炉非标定做电弧炉KDH-300

页面价格仅供参考,具体请联系报价起批量 价格 - ≧1 台

¥65000.00

- 产品型号:KDH-300

- 品 牌:酷斯特

- 所 在 地:河南郑州

- 更新日期:2025-12-19

选择 1台起售 ¥65000.00 库存充足 -+合计:1台总价:65000.00元(联系我时,请说明是从谷瀑网看到的,谢谢!)内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。河南酷斯特仪器科技有限公司 电话:0371-63365003 手机:15803995802 地址: 郑州市新郑市中德产业园

扫一扫,手机浏览

扫一扫,手机浏览